Micro Motors

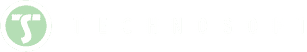

Slotless Brushless DC Motors

Innovative and independent patented ironless motor winding design delivers high power in a compact size. The brushless motors are manufactured in two versions to match wide application requirements: the TSU version is dedicated to standard speed and torque applications, and the TSH models have been optimized for higher speeds. Furthermore, the motors exhibit low noise, low inertia, and short response time to satisfy any dynamic application. The stator of a typical brushless motor is constructed using slots and the stator winding is shaped around them, this technology is very known and the issues that come with it aren’t to be neglected. The main issue is cogging torque which is a challenge in applications that require fast response, fast acceleration, and smooth operation.

Ironless Winding

Small Size (Ø13, Ø16 and Ø22 mm)

High Torque

High Speed

Modular design

Long operational lifetime

Cost effective

Silent operation

The flexible motor program allows system integrators to choose motor, feedback and gearbox in a solution tailored to machine requirements. Motors’ specifications, assembly options and accesories can be found in the complete catalog of the micro motors

The micro motors can be seamlessly controlled (position, velocity or torque) with the iPOS2401/iPOS360x family of drives providing a complete, cost effective motion solution.

Structure

TS Motors Line

Slotless BLDC Motor, Small Size, High Torque, High Speed

TSU13026

Slotless BLDC Motor, Φ13mm, 2.8mNm, 20000rpm

TSU13038

Slotless BLDC Motor, Φ13mm, 5.5mNm, 20000rpm

TSU16036

Slotless BLDC Motor, Ø16mm, 9.4mNm, 14000rpm

TSH16056

Slotless BLDC Motor, Φ16mm, 13.2mNm, 46000rpm

TSU22048

Slotless BLDC Motor, Φ22mm, 33.1mNm, 17000rpm

TSH22045

Slotless BLDC Motor, Φ22mm, 21.2mNm, 37000rpm

TSH22060

Slotless BLDC Motor, Φ22mm, 33.8mNm, 36000rpm

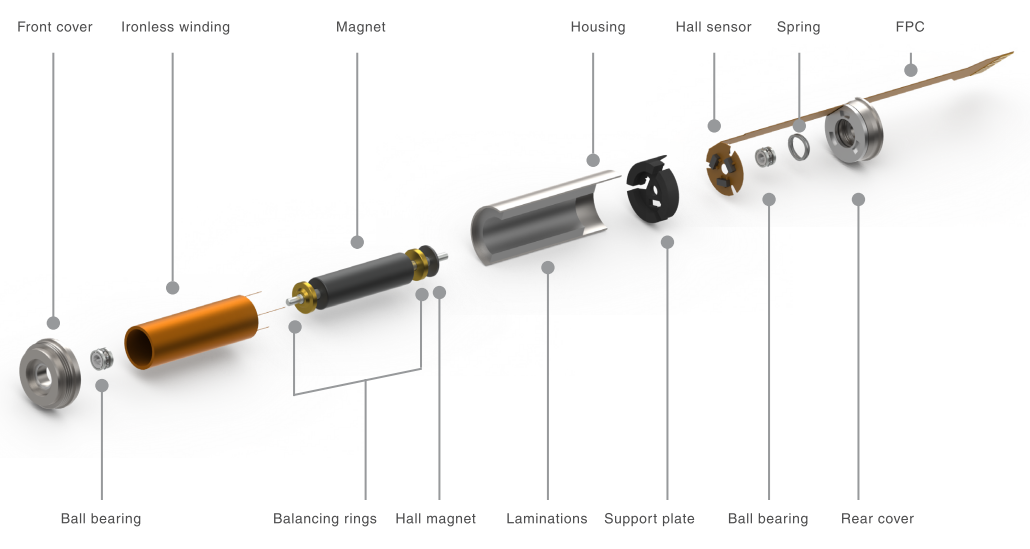

Coreless Brushed DC Motors

Technosoft coreless DC motors have major advantages compared to traditional DC motors including high efficiency, low mechanical time, and very low inertia. Because the core it’s constructed without iron and mass it’s low, it has the ability to accelerated and decelerated more faster than any other DC motor. The absence of iron eliminates cogging and the coreless motor operates smoothly, even at low speeds. One of the advantages we offer to the customers is modularization because they can be equipped with gearhead, encoders, and drive to provide a complete solution for your needs. We managed to bring the performance you want at a low price. Motors specifications, assembly options and accessories can be found in the complete catalog of the micro motors

Smooth control

Small Size (Ø8, Ø10, Ø13, Ø16, Ø17 and Ø24 mm)

High Torque

High Speed

Modular design

No cogging torque

Low weight

Cost effective

Structure

TC Motors Line

Coreless Brushed DC Motors, Small Size, High Torque, High Speed

TCU08017

Coreless Brushed DC Motor, Ø8mm, 0.6mNm, 5400rpm

TCU10017

Coreless Brushed DC Motor, Ø10mm, 0.71mNm, 5000rpm

TCU10025

Coreless Brushed DC Motor, Ø10mm, 1.63mNm, 6700rpm

TCU13020

Coreless Brushed DC Motor, Ø13mm, 1.83mNm, 8600rpm

TCU13028

Coreless Brushed DC Motor, Ø13mm, 3.48mNm, 7900rpm

TCU16025

Coreless Brushed DC Motor, Ø16mm, 2.23mNm, 8100rpm

TCU17025

Coreless Brushed DC Motor, Ø17mm, 3.89mNm, 8200rpm

TCU17035

Coreless Brushed DC Motor, Ø17mm, 7.72mNm, 9000rpm

TCU24032

Coreless Brushed DC Motor, Ø24mm, 10.92mNm, 8000rpm

Motor Applications

-

-

- Robotics

- Medical surgical tools

- Laboratory Automation

- Factory Automation

- Semiconductor Equipment

- Textile

-

dtrdddd