Technosoft intelligent drives/motors have the following communication interfaces: RS-232, USB, CAN-bus and EtherCAT. When using a CAN or EtherCAT master to control the motors, implementing complex motion sequences can be very difficult and time consuming. This is why our drives are able to work in a distributed intelligence way – between them and the master – which offers the possibility to call user defined functions stored in the drives memory by sending just one command from the host.

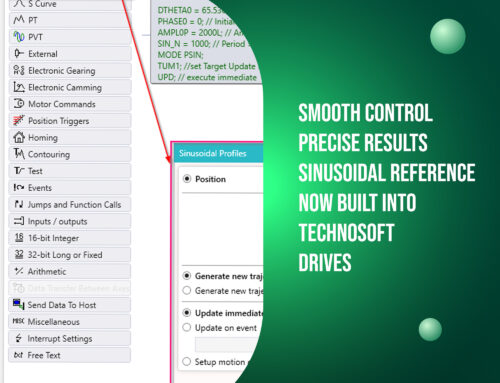

Using TML (Technosoft Motion Language), you can effectively distribute the intelligence between the master and the drives/motors in demanding multi-axis applications. Instead of controlling each movement step from the master, you can program the drives to execute various tasks and simply notify the master upon completion. The master’s job can then be made easier by just calling TML functions—with the ability to abort execution if needed—and receiving confirmation messages. Additionally, the drives can be programmed to send periodic updates, allowing the master to monitor task progress with minimal communication traffic.

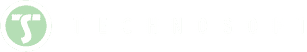

To control a motor, the drive must receive a reference, which can be either external (from the master) or internal (generated by the drive itself as programmed by the user). Using an internal reference simplifies application development and reduces network communication. In this case, the user provides basic input parameters, such as target speed or position, and the drive computes the appropriate motion trajectory. For instance, with an S-curve profile, entering just four variables enables the drive to generate and ensure that the motor follows the entire trajectory autonomously.

Beside the main component of a TML program, the user has at his disposal additional modules with the following purposes:

- Homing modes: select the homing procedure(s) to use from a list of already defined procedures

- Functions: create new TML functions and manage those defined: delete, rename, change their order in the program

- Interrupts: choose the TML interrupt service routines you want to view / change their default implementation

- Cam Tables: create, edit or import new cam tables to be used in the application

When set as master, the drive/motor sends its actual position or position reference via the CAN bus. When set as slave, the drive/motor executes a cam profile function of the information received from the master. The cam profile is defined as a table – a set of (X, Y) points, where X is the cam table input i.e. the master position and Y is the cam table output i.e. the corresponding slave position. Between the points the drive/motor performs a linear interpolation.

Master operation

Once at each slow loop sampling time interval, the master sends either its load position (APOS) or its position reference (TPOS) to the axis or the group of axes specified in the TML program.

Slave operation

The slaves can get the master position in two ways:

- Via a communication channel, from a drive/motor set as master

- Via an external digital reference of type pulse & direction or quadrature encoder. Both options share the same dedicated inputs. The pulse & direction signals are usually provided by an indexer while the quadrature encoder signals are received from the encoder on the master.

Camming

Electronic camming is an advanced trajectory generation method where a drive follows a predefined motion profile based on the position of a master axis. This profile—called the “cam table”—defines how the slave should move in relation to every point of the master’s position. Unlike a simple linear motion, camming enables non-linear, complex movements, which are essential for synchronized operations.

Camming is especially useful in systems where the load needs to accelerate, decelerate, pause, or reverse in a precise relation with the master position. Setting up camming involves creating the motion profile (the cam table) and ensuring that the slave is properly synchronized with the master. The system continuously interpolates between points in the cam table to generate a smooth motion.

Examples of some use cases include labeling machines, cutting applications and forming machines, where the slave must perform precise and repeatable tasks at specific points in the master’s cycle.

Gearing

Electronic gearing is a trajectory generation technique in which one or more axes are synchronized to a master axis using a constant ratio. The slave’s movement mirrors the master’s, either at the same rate or scaled up/down, defined by a gear ratio (e.g., 1:1, 1:2, etc.). This creates a connection that ensures smooth and consistent operation between the axes.

In this setup, the slave receives position data from the master through a communication channel or directly via encoders or pulse signals. The control system computes the slave’s movement in real-time, adjusting it continuously to match the master’s displacement based on the defined ratio. This method is designed for applications requiring synchronized, repeatable motion.

Electronic gearing is simpler to configure than camming. There’s no need for motion tables—just define the gear ratio and the direction (positive or reversed). Gearing is reliable and efficient in maintaining alignment and timing across multiple drives in high-speed operations.

Homing

The homing procedure is a set of specific movements / actions that a system must perform – usually once after power-on or reset – as part of the initialization process before the machine is ready for operation. Our drives are capable of performing such tasks independently. This simplifies the programming and integration process for the master controller. Instead of having to manage every detail of the homing sequence—such as issuing low-level movement commands, monitoring limit switches or current thresholds, and determining when the home position is reached—the master can simply trigger the appropriate homing function already built into the drive. In this way, the master focuses only on higher-level tasks while offloading the lower-level motion logic to the drive, leading to a cleaner, more maintainable control architecture.

Conclusion

In conclusion, Technosoft intelligent drives and motors offer easy-to-use and flexible solution for complex motion control applications. By distributing intelligence between the master and the drives, they significantly reduce the communication overhead and the development time. Through TML programming, users can implement advanced motion functions directly at the drive’s level, enabling precise control with minimal master intervention. The versatility of our drives, including their support for the above detailed camming, gearing and homing procedures, ensures efficient performance across a wide range of industrial automation projects.

Contact our team today!