Intro

Technosoft intelligent drives and motors are built to integrate effortlessly into a wide range of industrial environments. Whether you’re upgrading legacy equipment or developing a new automation system, our devices offer flexible protocol support and multiple interface options — so you can focus on performance, not compatibility.

Overview of Supported Communication Interfaces

Depending on the product model, Technosoft intelligent drives and motors may communicate using the following interfaces:

- RS-232 (present on all models)

- USB

- CAN-bus (supporting multiple protocols)

- EtherCAT®

- Ethernet access via Technosoft Ethernet adapters (RS232 or CAN based)

Industrial: RS-232 Communication

All Technosoft intelligent drives and motors are equipped with RS-232, a full-duplex, point-to-point communication interface. It’s ideal for configuration, diagnostics, and small-scale control systems, with data rates up to 115200 bps.

Benefits:

- Widely supported across industrial systems

- Reliable, and easy to implement

Plug-and-Play: USB Communication

The newer generation of our drives comes with native USB 2.0 support, making it easier to connect directly to a PC or host system. It’s a straightforward way to handle setup, testing, or updates — with transfer speeds up to 480 Mbps.

Benefits:

- No external converters needed

- Plug-and-play convenience

- High data transfer speed

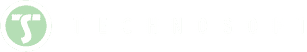

Powerful Networking: CAN Communication

Technosoft drives that include a CAN-bus interface can be configured to use either:

- TMLCAN – Technosoft’s proprietary protocol (CAN 2.0B, 29-bit identifier)

- CANopen – Based on CiA standards (CAN 2.0A, 11-bit identifier)

TMLCAN allows for drive-to-drive communication and autonomous control without a master. Any drive can assume the role of a master, synchronize motion across the network and directly exchange TML (Technosoft Motion Language) commands with the other drives.

Key features:

- No master required

- Drives can coordinate and execute motion sequences by exchanging TML commands over the CAN network

- Ideal for distributed systems

In CANopen mode, the drives comply with motion control standards (CiA 301, 305, 402) and can be seamlessly integrated into broader automation systems controlled by a CANopen master.

Key features:

- Industry-standard protocol

- Widely compatible with industrial automation environments

- Speeds up to 1Mbps, Half-duplex

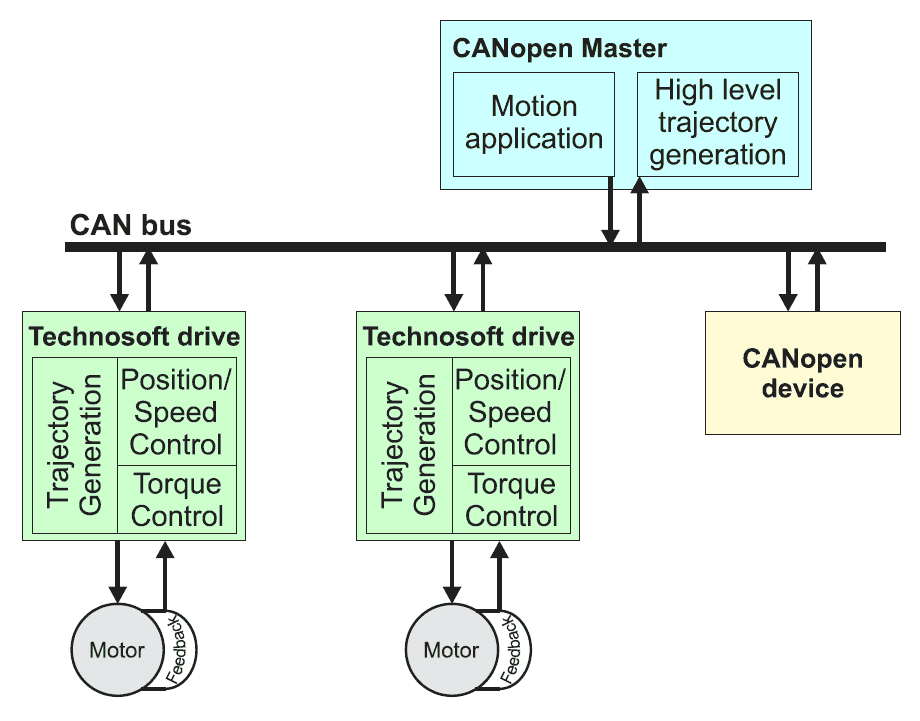

High-Speed Industrial Ethernet: EtherCAT® communication

For real-time motion control applications, Technosoft drives support EtherCAT® (Ethernet for Control Automation Technology) — a fast, open Ethernet-based fieldbus widely used in advanced automation systems.

Supported features include:

- CoE (CAN Application Protocol over EtherCAT) – Combines the structure of CANopen with EtherCAT’s performance

- FoE (File-over-EtherCAT) – Efficient firmware and file transfer

- EoE (Ethernet-over-EtherCAT) – Enables regular Ethernet traffic over the EtherCAT network

Key features:

- Standardized Communication Protocol

- Flexible topology

- Real-time operation with precise synchronization

- Speeds up to 100Mbps, full duplex

Remote connectivity: Ethernet communication

Technosoft also offers Ethernet adapters, expanding access to drives from any location with internet over Ethernet connectivity:

- RS232-to-Ethernet Adapter

- CAN-bus-to-Ethernet Adapter

Once the adapter is integrated in the LAN (local area network) it bridges the Technosoft CAN network or individual RS-232 entry points to Ethernet and any connected Technosoft drive becomes accessible via the internet with EasyMotion Studio environment or a custom application running on virtually any physical location. This setup enables remote access for configuration, motion programming, real-time control, and system diagnostics — all through an Ethernet connection.

Highlights:

- Allows remote TML command communication

- Works with any Technosoft drive

- Ethernet protocol packs/unpacks TML into proper message formats

Conclusion

Technosoft’s flexible, multi-protocol communication architecture ensures that our drives adapt to your system — not the other way around.

✅ Integrate seamlessly into modern or legacy automation setups

✅ Choose from industry-standard or proprietary protocols

✅ Use centralized or distributed control strategies

✅ Configure, command, and monitor remotely

Whether you’re retrofitting existing equipment or designing a new platform, Technosoft drives are ready to connect. With support for a broad range of industrial protocols, you gain the freedom to build automation systems that are smarter, more agile, and easier to maintain.

Contact our team today!