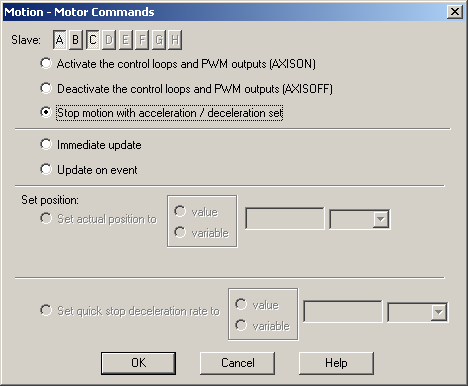

The “Motion - Motor Commands” dialogue allows you to send one of following commands to the slave drive/motor:

| • | Activate/deactivate the control loops and the power stage PWM output commands (AXISON / AXISOFF) |

| • | Stop the motor with deceleration set in TML parameter CACC |

| • | Change the value of the motor position and position reference |

| • | Set deceleration rate for quick stops |

Remark: The AXISON, AXISOFF and STOP commands can be sent, also, to several slaves.

The destination of the motor command is selected from the Slave list.

Remark: The Slave list contains all the slaves selected in the Axis Selection window, including the motion controller. If there are no slaves selected then the motor command will be executed locally by the drive part of the motion controller.

Select Activate the control loops and PWM outputs (AXISON) to restore normal drive operation after an AXISOFF command. Typically, this situation occurs at recovery from an error, following the fault reset command FAULTR, or after the drive/motor ENABLE input goes from status disabled to status enabled.

Select Deactivate the control loops and PWM outputs (AXISOFF) when a fault condition is detected, for example when a protection is triggered. This command disables the motor control (all the control loops), all the PWM output commands for the power stage (all the switching devices are off) and also the reference generator.

Fault conditions trigger TML interrupts. Each drive/motor has a built-in set of TML interrupt service routines (ISR) which are automatically activated after power-on. In these routines, the default action for fault conditions is an AXISOFF command. If needed, you may replace any built-in ISR with your own ISR and thus, adapt the fault treatment to your needs.

After a fault condition, the actual values of the load position and speed (which continue to be measured during the AXISOFF condition) may differ quite a lot from the values of the target position and speed as were last computed by the reference generator before entering in the AXISOFF condition. Therefore, a correct fault recovery sequence involves the following steps:

| • | Set the motion mode, even if it is the same. Motion mode commands, automatically set the target update mode zero (TUM0), which updates the target position and speed with the actual measured values of the load position and speed |

| • | Execute update command UPD |

| • | Execute AXISON command |

Remark:

| • | In the Drive Status control panel, SRL.15 bit shows the AXISON/AXISOFF condition and SRH.15 bit shows a fault condition |

| • | In EasyMotion Studio, ENDINIT and AXISON commands are automatically included in the TML program, just before your first TML command from the main section. Therefore you don’t need to include them in your motion program. |

Select STOP to stop the motor with the deceleration rate set in TML parameter CACC. The slave drive/motor decelerates following a trapezoidal position or speed profile. If the STOP command is issued during the execution of an S-curve profile, the deceleration profile may be chosen between a trapezoidal or an S-curve profile (see S-curve dialogue settings). You can detect when the motor has stopped by setting a motion complete event on motion controller and waiting until the event occurs. The STOP command can be used only when the slave drive/motor is controlled in position or speed.

Remarks:

| • | In order to restart after a STOP command, you need to set again the motion mode. This operation disables the stop mode and allows the motor to move |

| • | When STOP command is sent via a communication channel, it will automatically stop any TML program execution, to avoid overwriting the STOP command from the TML program |

Choose Immediate Update to send an update command UPD to one or several slave drives/motors. When this command is received, the last motion mode programmed together with the latest motion parameters are taken into consideration. The immediate update command is available in all the dialogues setting a motion mode and normally it is called from these dialogues. The immediate update command is useful when the motion mode is set in advance for a later execution, which is started with a separate update command. In a similar way you may use the Update on event command.

You can set / change the referential for position measurement by changing simultaneously the load position APOS and the target position TPOS values, while keeping the same position error at any moment during motion. Use the edit field from set actual position value to specify the new motor position value.

Remarks: In the case of steppers controlled in open loop, this command changes only the target position TPOS to the desired value.

The deceleration rate for quick stops can be set/change selecting the option Set quick stop deceleration rates. To assign an immediate value select option value and fill the associated field, if you want to assign the value of a variable then select variable and in the associated field write the name of the variable.

OK: Close this dialogue and save the motion sequence in your motion sequence list.

Cancel: Close this dialogue without saving the motion sequence in your motion sequence list.

Help: Open this help page.

See also:

Motor Commands – TML Programming Details