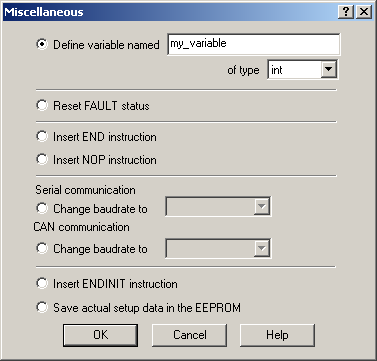

The “Miscellaneous” dialogue allows you to:

| • | Declare user variables |

| • | Reset/exit the drive/motor from the FAULT status |

| • | Execute less frequently used TML commands like: END, NOP, ENDINIT |

| • | Change the CAN bus and serial RS232 / RS485 communication settings |

| • | Save actual setup data from RAM into the EEPROM in the setup table |

Select Define variable named if you want to define a new variable. Specify the variable name in the next field and choose the variable type from the list. The options are: int, fixed or long. A variable of type int is a 16-bit signed integer. A variable of type long is a 32-bit signed integer. A variable of type fixed is 32-bit wide and is used for signed fixed-point representations with 16MSB the integer part and 16LSB the factionary part.

Select Reset FAULT status to exit a drive/motor from the FAULT status in which it has entered due to an error. After a fault reset command, most of the bits from error register MER are cleared (set to 0), ready output is set to ready level, error output is set to no error level and drive/motor returns to normal operation.

Remarks:

| • | The FAULT reset command does not change the status of MER.15 (enable input on disabled level), MER.7 (negative limit switch input active), MER.6 (positive limit switch input active) and MER.2 (invalid setup table) |

| • | The drive/motor will return to FAULT status if there are errors when the FAULTR command is executed |

Select Insert END instruction to introduce in your TML program the instruction END. When END is executed, the TML program execution is stopped.

Remark: It is mandatory to end the main section of a TML program with an END command. All the TML functions and the TML interrupt service routines must follow after the END command. EasyMotion Studio automatically handles these requirements, when it generates the TML program to be compiled and downloaded into the drive.

Select Insert NOP instruction to introduce a NOP (No operation) instruction. It can be used as a delay between two motion sequences / instructions.

In the Serial communication section, choose Change baudrate to if you want to change the drive baud rate for RS-232 and RS-485 communication. Choose from the drop list one of the available baud rates: 9600, 19200, 38400, 56000 and 115200.

Remarks:

| 1. | The drives/motors default serial baud rate after power on is 9600 baud, unless another value was saved in the setup table. When you start EasyMotion Studio, the drives/motors serial baud rate is automatically adjusted to the last value selected at Communication | Setup in the Baud Rate field. |

| 2. | Use this command when a drive/motor operates in AUTORUN (after power on starts to execute the TML program from the EEPROM) and it must communicate with a host at a baud rate different from the default value. In this case, the TML program must start with a serial baud rate change. |

| 3. | An alternate solution to the above case is to set via EasyMotion Studio the desired baud rate and then to save it the EEPROM, with command SAVE. After a reset, the drive/motor starts directly with the new baud rate, if the setup table was valid. Once set, the new default baud rate is preserved, even if the setup table is later on disabled, because the default serial baud rate is stored in a separate area of the EEPROM. |

In the CAN communication section, choose Select Set CAN baudrate to if you want to change the baud rate for CAN-bus communication. Choose from the drop list one of the available CAN baud rates: 125kb, 250kb, 500kb, 800kb, 1Mb.

Remarks:

| 1. | The drives/motors default CAN baud rate after power on is 500kb, unless another value was saved in the setup table. In EasyMotion Studio, at Communication | Setup, in the Baud Rate field, you must choose the same value as the default CAN baud rate of the drives/motors value. This selection refers ONLY to the CAN bus interface of your PC |

| 2. | Use this command when a drive/motor operates in AUTORUN (after power on starts to execute the TML program from the EEPROM) and it must communicate with a host at a baud rate different from the default value. In this case, the TML program must start with a CAN baud rate change. |

| 3. | An alternate solution to the above case is to set via TML command CANBR the desired CAN baud rate and then to save it the EEPROM, with command SAVE. After a reset, the drive/motor starts directly with the new CAN baud rate, if the setup table was valid. Once set, the new default CAN baud rate is preserved, even if the setup table is later on disabled, because the default CAN baud rate is stored in a separate area of the EEPROM. |

Select Insert ENDINIT instruction to introduce an ENDINT (end of initialization) instruction. This command uses the available setup data to perform key initializations, but does not activate the controllers or the PWM outputs. These are activated with the AXISON command

Remarks:

| 1. | After power on, the ENDINIT command may be executed only once. Subsequent ENDINIT commands are ignored. |

| 2. | The AXISON command must be executed after the ENDINIT command |

| 3. | Typically, the ENDINIT command is executed at the beginning of a TML program and may be followed by the AXISON command even if no motion mode was set. In the absence of any programmed motion, the drive applies zero voltage to the motor. |

| 4. | In EasyMotion Studio, ENDINIT and AXISON commands are automatically included when a TML program is generated. Hence you can start directly with the motion programming |

Select Save actual setup data in the EEPROM to insert a SAVE instruction in the TML program. When SAVE instruction is executed, the actual values of the TML parameters are copied from the RAM memory into the EEPROM memory, in the setup table. Through this command, you can save all the setup modifications done, after power on initialization.

OK: Close this dialogue and save the TML commands in your motion sequence list.

Cancel: Close this dialogue without saving anything in your motion sequence list.

Help: Open this help page

See also:

Miscellaneous commands – TML Programming Details